UTAS Motorsports Team

About us

The UTAS Motorsports Team is a group of dedicated students who participate in the annual Formula Society of Automotive Engineers (FSAE) Australasia competition. This competition challenges university students to design, build and race a small formula-style race car against universities from across Australasia. We follow a 2-year design cycle of redesigning and optimising an electric car, assembling a new car from the ground up each year and iteratively improving the vehicle. The team is composed of students who are keen to learn about design and engineering practices and work together as parts of a team – we are volunteers without academic credit or pay.

The FSAE competition consists of several events. Technical inspections are undergone by the scrutineers who will ensure that each car is rules compliant before allowing each team to run. This rigorous process often means teams will not get to drive their car in competition. Static events analyse the teams' design and marketing abilities and how the team operates. These are: design event, cost event and business event. Finally, are the dynamic events, which involve the dynamic testing of the car. The events for this are: acceleration, skidpan, autocross, endurance, and efficiency. These are the ultimate test of the team's car and drivers. In 2024, the UTAS Motorsport team achieved 2nd place in the Cost and Efficiency events for Electric Vehicles.

<iframe width="560" height="315" src="https://www.youtube.com/embed/7Frp0d9FL3Q?start=2466" frameborder="0" allowfullscreen></iframe>

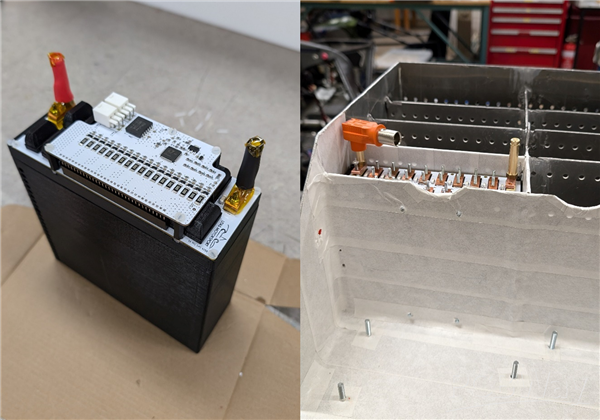

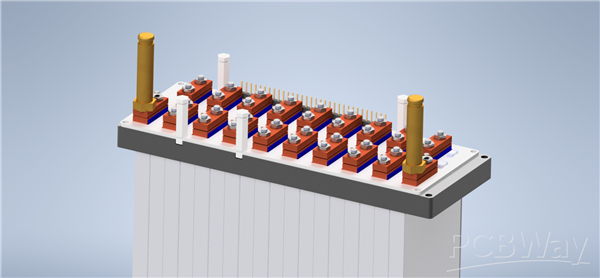

Rather than assembling our car entirely from off-the-shelf parts, we try to design as many components as possible from scratch, including custom electronics. For example, we use a custom Battery Management System. PCBWay's PCB printing service has allowed us to design our own bespoke BMS (among other components), which gives our members experience with electronics design and provides the team an advantage in competition. This forms part of our complete bespoke battery package, which we need help in manufacturing key components.

How PCBWay can help

Our accumulator is made of 8 segments, each with 18 Lithium polymer cells connected in series. The cells' tabs are clamped together by copper bus bars, which can carry high current without solder. The bus bars are also used for individual monitoring from the cell monitoring PCB. We would appreciate the use of PCBWay's CNC service to machine new brass bus bars, which will enable us to assemble a new battery.

- Formula Student

- SAE

- EV

- FSAE

You might like

- Comments(0)

- Likes(0)