Team Fateh - The FSAE(Formula Student) team of TIET

Project Story – Team Fateh | Formula Student EV

What is our project about?

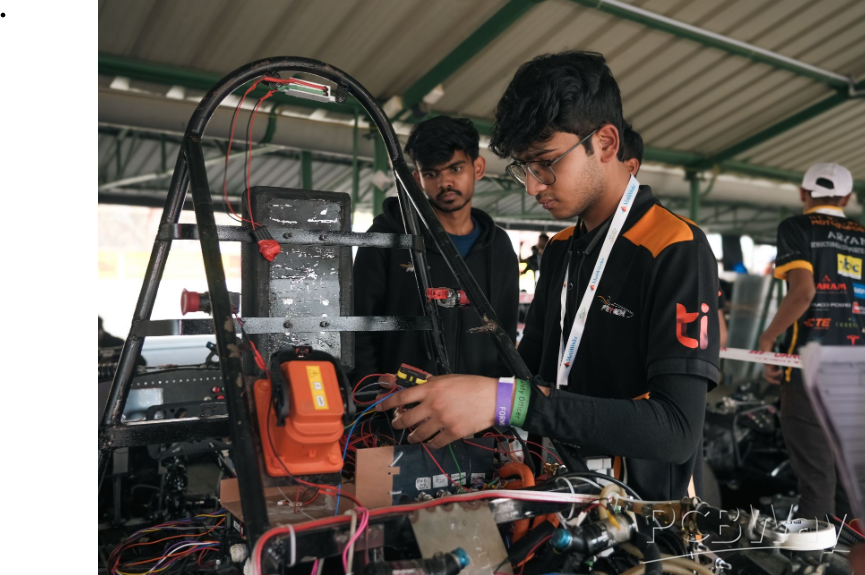

Founded in 2008,Team Fateh is the official Formula Student team of Thapar Institute of Engineering & Technology. Our project focuses on designing, developing, and racing a high-performance electric Formula-style vehicle to compete in national and international competitions such as SUPRA SAE 2025 and Formula Bharat 2026.

This vehicle is engineered entirely by undergraduate students and includes several custom-designed embedded systems and printed circuit boards (PCBs) critical to electric vehicle operation. Our car integrates systems like a battery management system, data acquisition modules, and custom telemetry—all developed in-house.

Our mission is to advance student-led innovation in sustainable motorsports, pushing the boundaries of electric vehicle performance, safety, and control.

Why did we decide to make it?

We took on this project to address real-world challenges in the field of sustainable mobility and intelligent electric vehicle systems. The Formula Student platform allows us to apply classroom knowledge to high-impact engineering work, collaborate across disciplines, and prepare ourselves for careers in the automotive, motorsport, and embedded systems industries.

As electric mobility gains global momentum, we wanted to contribute meaningfully by designing our own EV components from scratch, including the electronics that monitor, control, and optimize vehicle performance.

How does it work?

Our vehicle is a single-seater electric race car designed with integrated embedded systems developed in-house. All PCBs are custom-designed using professional EDA tools and tested extensively before vehicle integration. Key components include:

Battery Management System (BMS): Manages cell voltages, state of charge, and thermal safety.

Data Acquisition Unit (DAQ): Collects real-time vehicle parameters and logs them for performance analysis and validation.

Vehicle Control Unit (VCU): Implements drive logic, traction control, pedal plausibility checks, and safety interlocks.

Driver Dashboard and Interface Boards: Provide live vehicle status and configurable controls to the driver.

Low Voltage (LV) Distribution Board: Powers and protects all 12V systems with fuses, relays, and isolation for high-reliability operation.

Safety & Shutdown Circuit Boards: Critical for meeting competition safety regulations. These include TSAL (Tractive System Active Light), BSPD (Brake System Plausibility Device), IMD (Insulation Monitoring Device interface),Precharge and discharge circuits, PDU (Power Distribution circuits).

All systems are integrated, tested on the bench, and then validated on the vehicle. PCBs are designed to be compact, robust, and optimized for signal integrity and EMI resilience.

- Electric Vehicles

- Automotive and Mobility

- Circuit testing and validation

- Circuit Designing

- High Voltage

- Safety Circuit

- Formula Student

You might like

- Comments(0)

- Likes(1)

-

-

-

Engineer

Engineer

-