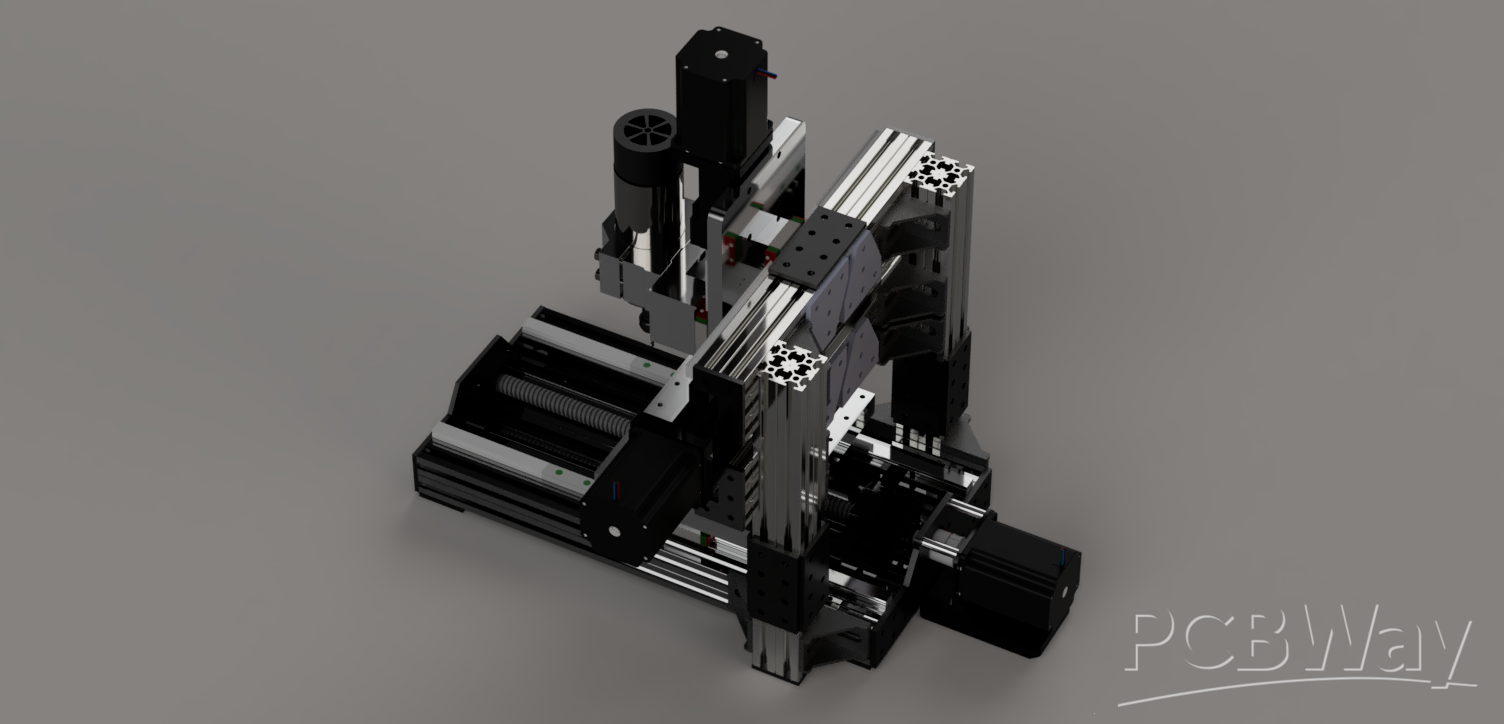

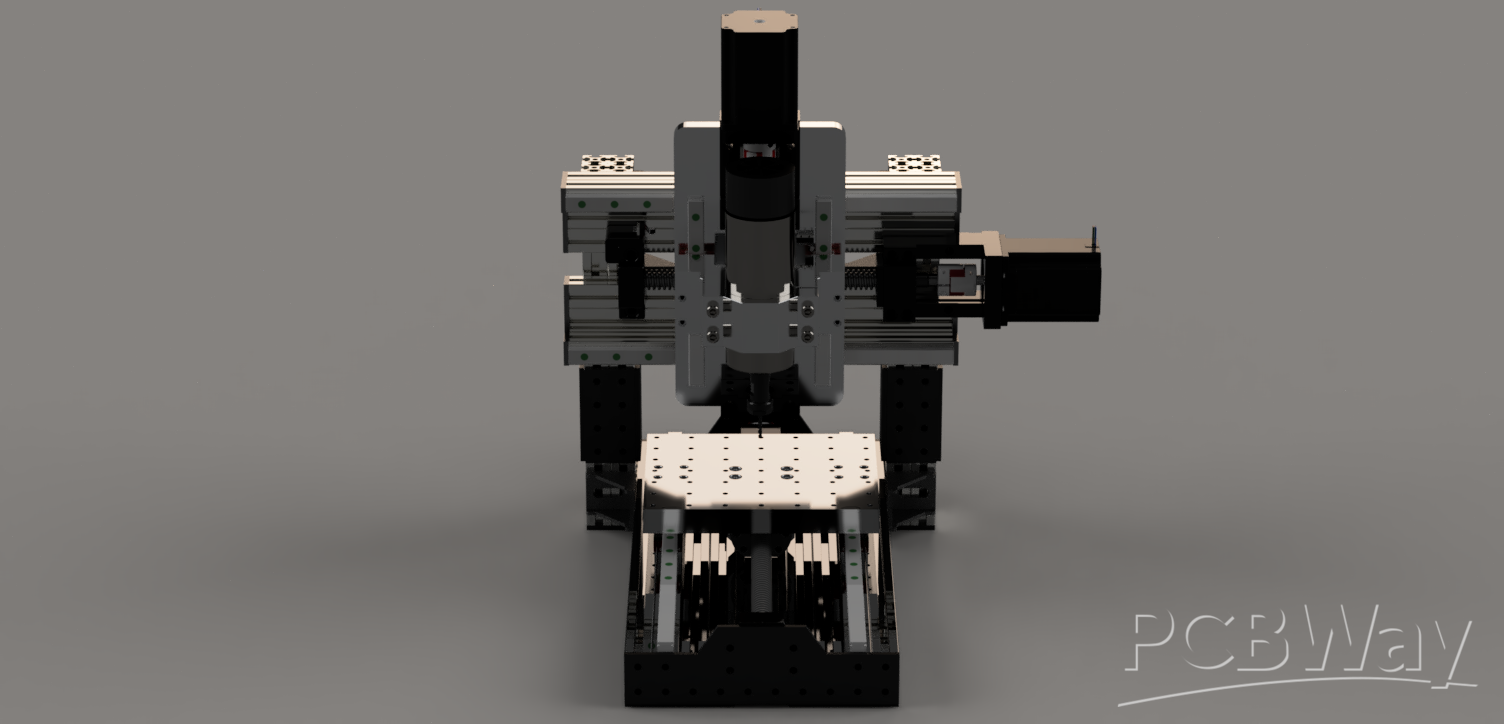

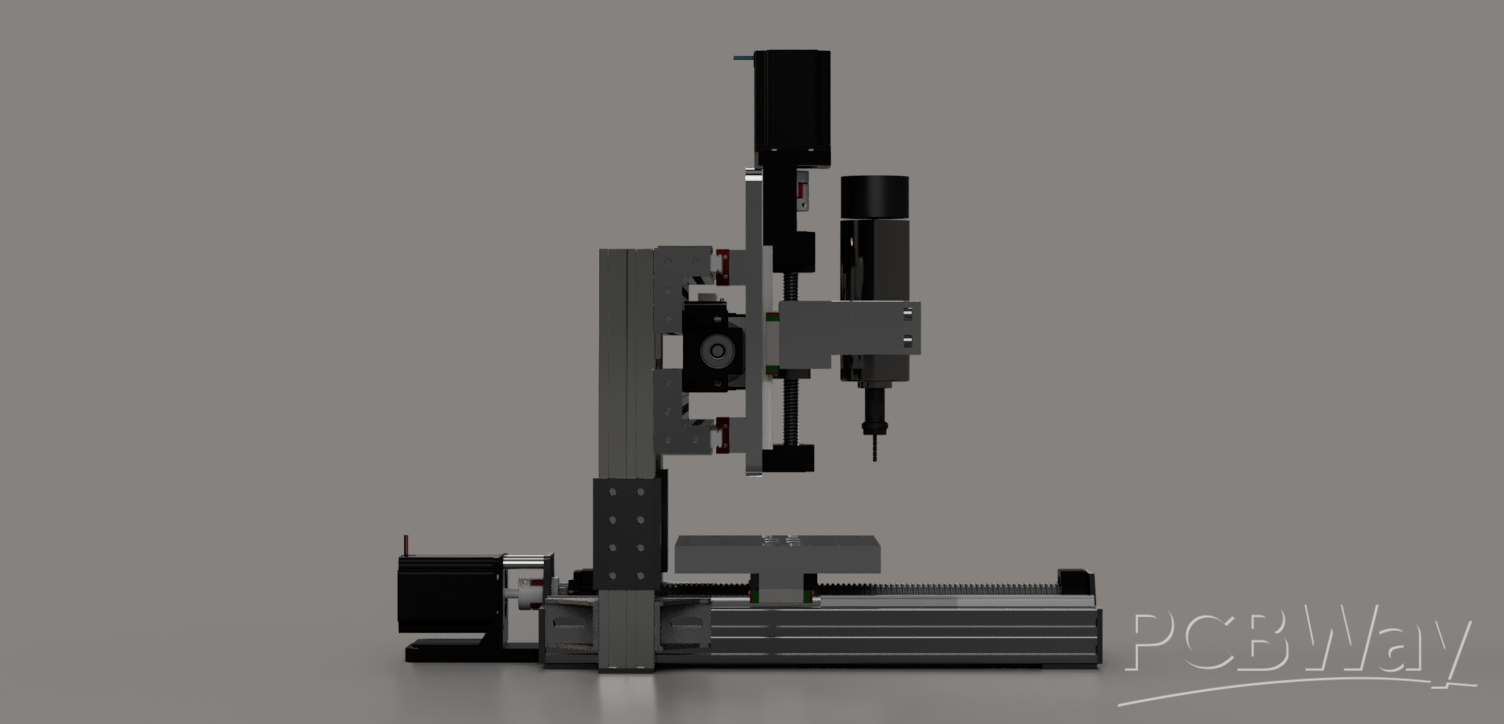

Forge: An ultra-rigid mini CNC mill!

My name is Sidd. I'm a student from Washington, and I enjoy designing and building things such as laser cutters and 3d printers! However, as my most ambitious project yet, I designed a CNC mill. I didn't want to make something that could only do softer material such as wood; I wanted a mill for metal parts, something I didn't have access to. I learned so much in the process and I ended up with a very rigid design that can handle even harder materials than aluminum!

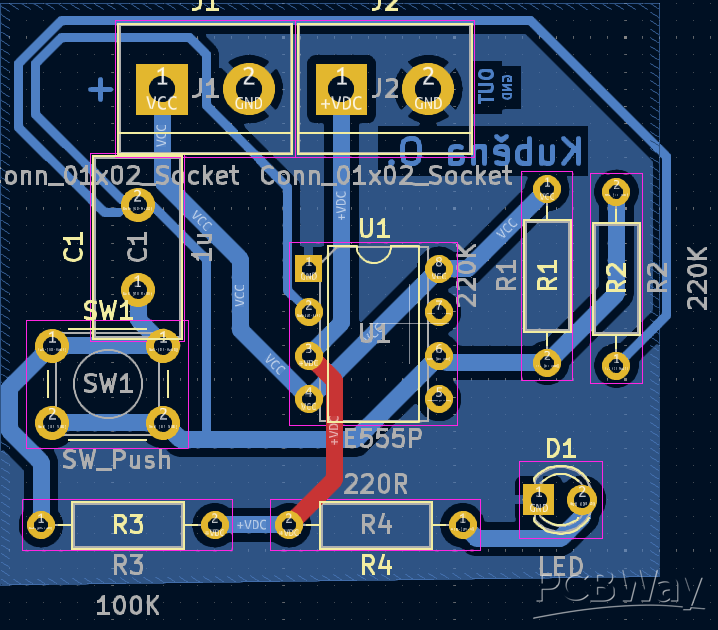

Forge is a mini CNC mill that is capable of milling metals such as aluminum, brass, and copper. It fires on all pistons, with an all-steel/aluminum build (not a single 3D-printed part!), ultra-rigid construction, 500W BLDC spindle, high-torque NEMA 23 stepper motors, am 20mm thick aluminum fixture plate, ballscrews, linear rails, and limit switches!

The machine aims to push the boundaries of at-home milling, from copper-clad FR4 to thick pieces of aluminum.

I designed Forge with Fusion 360 due to my constant draw towards new materials that I've always wanted to use in projects. Stuff like plexiglass, metals, and wood! I wanted to expand my material selection further by adding aesthetic, cheap, and structural materials. As well as this, I wanted a precise machine that I designed myself, to be powerful, useful, and sleek.

Here are some renders of the CNC mill!

- rigid

- metal

- ballscrews

- 500wspindle

- nema23

- build

- cnc

- mill

You might like

- Comments(1)

- Likes(1)

-

-

Ondřej Kuběna

Ondřej Kuběna Aug 11,2025

Aug 11,2025Hello, this is a great project!<br> I have a question, did PCBWay sponsor the whole project?<br> Thank you.

-

-

-

Engineer

Engineer

-