Crafting Competitive Underwater Robots

Robo-Tech Team

Robo-Tech is a student-led robotics team from Alexandria University, Egypt, with over a decade of hands-on experience in designing and building competitive, mission-driven robots. From land-based rovers to advanced Remotely Operated Vehicles (ROVs), we engineer systems that take on real-world challenges, pushing the boundaries of student innovation in national and international arenas.

Our project is to design, build, and operate a next-generation underwater ROV that can compete in high-level international robotics competitions. The robot must complete real-world tasks such as object retrieval, navigation, environmental sampling, and even automated inspections, all while being fully tethered, pressure-tolerant, and electrically safe.

What makes our ROV truly unique is the level of custom electronics integrated into every core function. Our goal is to build a highly modular, compact, and power-efficient robotic system that can perform flawlessly in any underwater environment.

Egypt has great potential in the field of marine robotics, but students rarely get the hands-on experience needed to pursue it. That’s why our team has chosen to specialize in underwater systems: we want to push the limits of what student engineers can build, not just for competition, but to inspire real-world innovation and empower the next generation of engineering students.

By participating in competitions like MATE and UMVC, our members gain advanced practical skills in embedded systems, power electronics, sensors, signal integrity, system integration, and ROS (Robot Operating System).

Our ROV - LEVIATHAN II

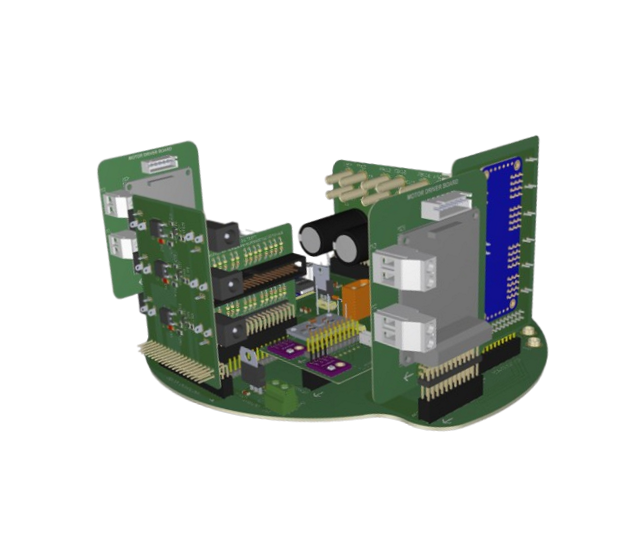

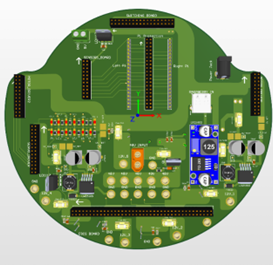

The ROV is built around a set of custom-designed PCBs, each performing a dedicated role. Here’s a breakdown of how it all works:

PCB Boards:

The Main Board acts as the central hub, linking all auxiliary boards and managing power distribution. It steps down from 48V to 12V, 5V, and 3.3V, with built-in protection against overvoltage, reverse polarity, and thermal overload.

All sensors are integrated into a dedicated Sensor Board, which houses a 9-axis IMU, barometric pressure sensor, ADC, and expansion space for future sensors. This board consolidates all data through I2C and SPI, giving the system real-time awareness and flexibility.

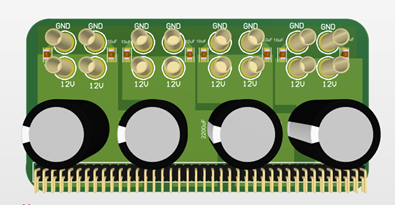

Our ESC Interface Board powers up to six ESCs for the ROV’s BLDC thrusters. It delivers a stable 12V output via bullet connectors, backed by decoupling capacitors to minimise noise and ripple under load.

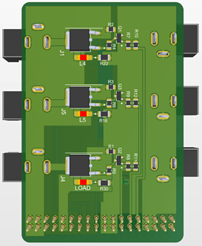

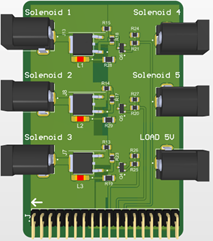

The Switching Unit, a six-channel MOSFET-based circuit, controls DC valves, lights, and other binary loads. Built on a compact double-layer PCB, it includes IDC connectors for easy replacement and expansion.

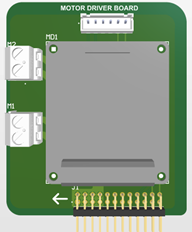

For auxiliary mechanisms, we developed two custom Motor Driver Boards to reduce cost and improve efficiency. Using just two PWM lines per motor, the board controls grippers and other actuators with precise current handling. Two variants support different drive configurations.

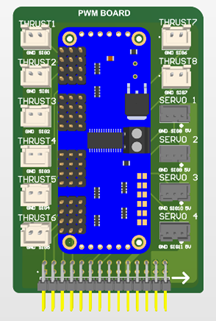

The PWM Interface Board serves as the control hub for precise motor and thruster management. Built around a 16-channel servo driver, it delivers clean, isolated PWM signals to motor drivers and ESCs while minimizing EMI risks. What sets it apart is its smart monitoring system, continuously tracking the current draw of each thruster and immediately flagging anomalies, ensuring stable and safe operation throughout every mission.

.

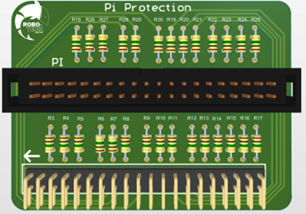

To safeguard the Raspberry Pi and core control systems, the Protection Board provides a critical layer of electrical and thermal defence. It integrates fuses, crowbar circuits, GPIO clamping, and onboard diagnostics to protect against voltage spikes, current surges, and overheating, ensuring stable and reliable operation in demanding environments.

Why PCBWay?

Bringing a robot like this to life takes more than just design and code; it takes time, testing, and a team that’s committed to getting it right. We constantly prototype and refine our PCBs throughout the year to ensure they perform reliably under real-world conditions.

The biggest challenge we face isn’t building the systems, it’s keeping up with the costs and timelines of manufacturing. That’s why we believe partnering with PCBWay would make a meaningful difference.

Your support wouldn’t just help us build robots, it would accelerate innovation, expand opportunities for our team, and shape the engineers of tomorrow. With PCBWay by our side, we can move faster, aim higher, and keep delivering the level of quality demanded on the international stage.

We’re not just preparing for competitions; we’re preparing for the future.

And we’d be honoured to have PCBWay as a core part of that mission.

- ROV underwater robot Robo-Tech student project

You might like

- Comments(0)

- Likes(0)